Investigating the Capability of Radio Frequency (RF) Heating in Splitting Closed-Mouth Pistachios and Evaluating Temperature Distribution Uniformity in Bulk Loads

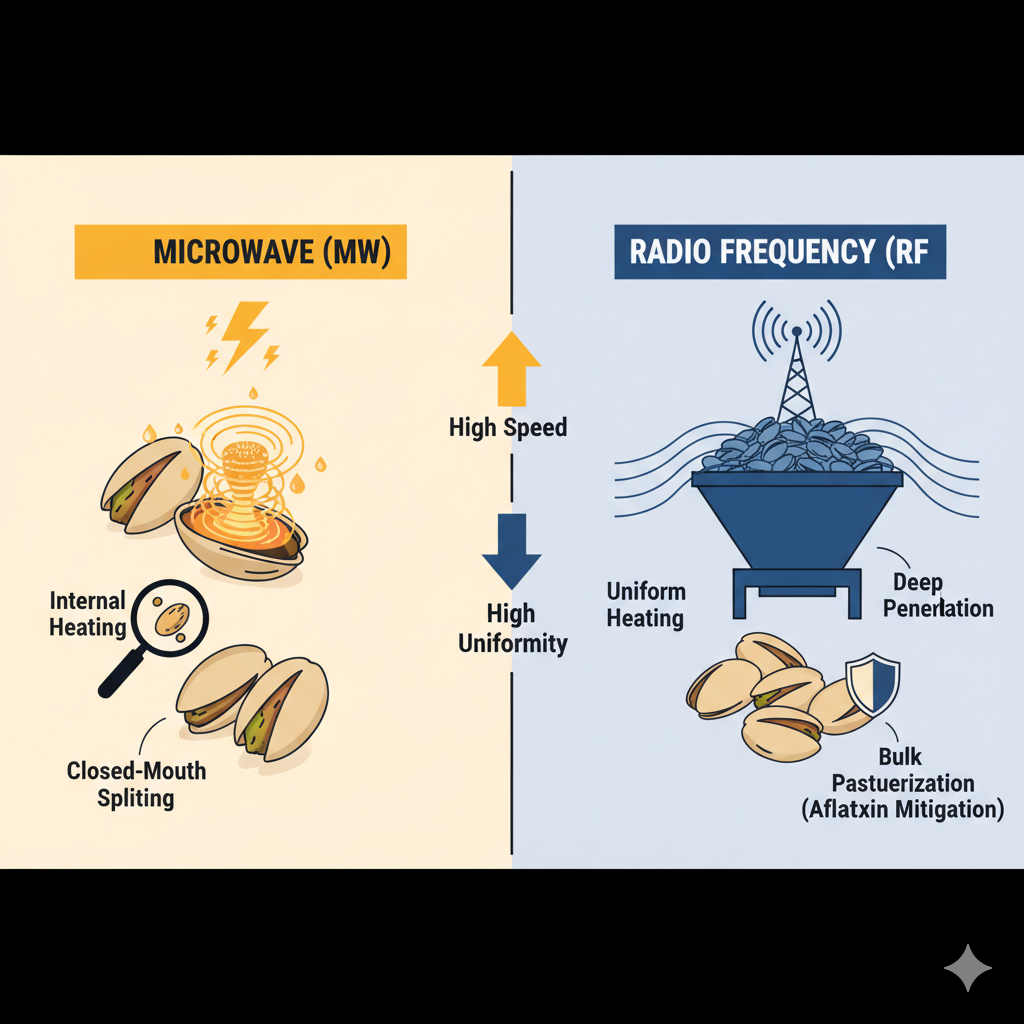

AbstractThis paper investigates the potential of Radio Frequency (RF) technology for splitting closed-mouth pistachios and compares its temperature distribution uniformity with MW in industrial bulk loads. The splitting process is based on the mechanism of thermal shock and internal vapor pressure buildup. RF treatment (at a frequency of 27.12 \text{ MHz}) was applied to closed-mouth pistachio samples with controlled moisture content. Results indicated that RF heating, due to its deep and more uniform penetration in bulk volumes, could open the closed-mouth pistachios with a splitting rate exceeding 85 \text{ percent}. Crucially, RF generated a lower temperature gradient within the bulk, which is vital for uniform roasting in industrial settings.

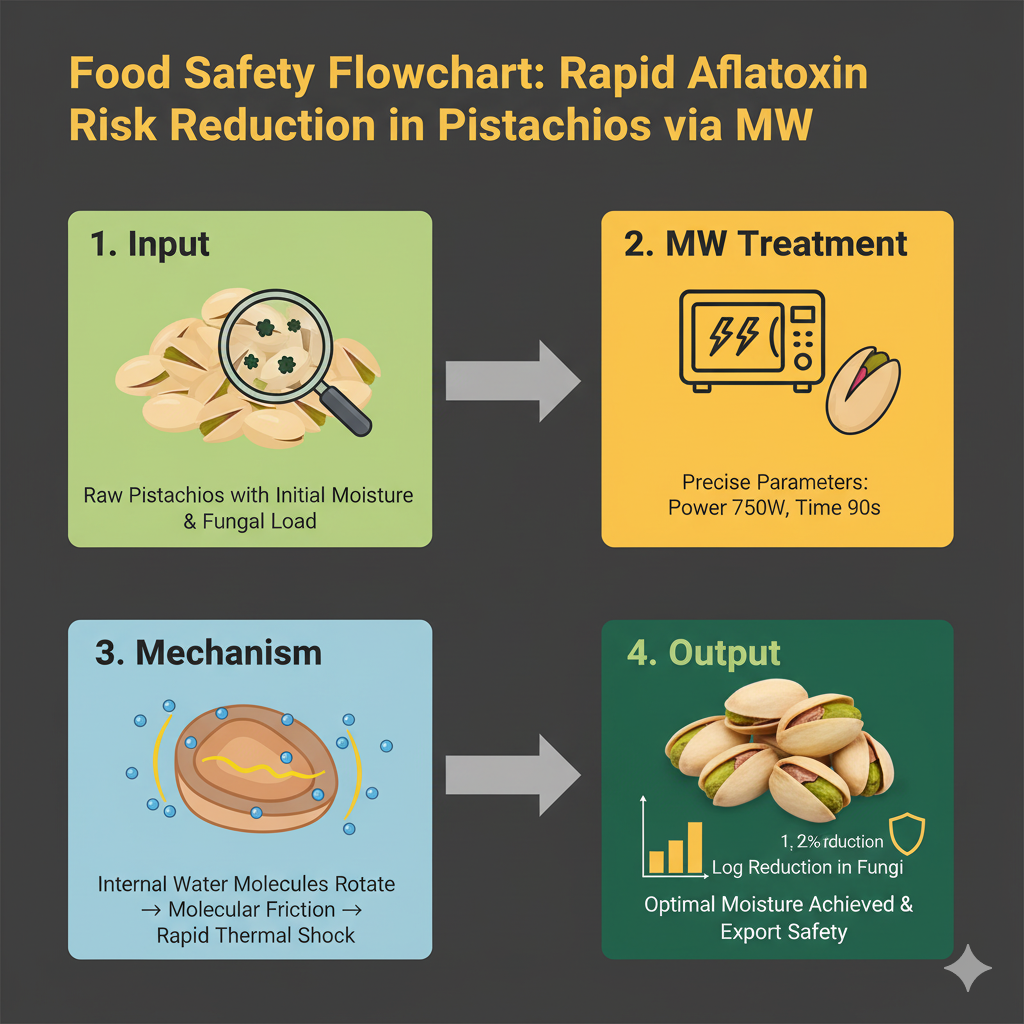

1. IntroductionClosed-mouth pistachios (with a low natural splitting rate) constitute a significant portion of the harvested crop, and processing them (splitting or separation) is an economic challenge. Traditional mechanical methods often result in kernel damage and increased waste. Radio Frequency heating, with its deep and uniform heating capability, offers the potential to create internal stress to fracture the shell without mechanical damage.2. Materials and MethodsClosed-mouth Fandoghi pistachios with adjusted moisture content (12 \text{ percent} wet basis) were used. * Splitting Experiment: Samples were placed in an RF chamber and heated at various power levels to generate the necessary vapor pressure for splitting. The percentage of naturally opened pistachios after treatment was recorded.

* Temperature Uniformity: Both numerical simulation (FEM) and experimental measurements across different points of a bulk pistachio load (5 \text{ kg}) were used to determine the temperature distribution uniformity and identify potential hot and cold spots.3. Results and Discussion3.1. Efficacy of Closed-Mouth Pistachio SplittingUnder optimal RF conditions, the splitting rate reached 87 \text{ percent}. The key factor was RF’s ability to homogeneously distribute heat within the shell and kernel, ensuring that the necessary stress for fracture was applied effectively throughout the shell. This approach minimizes mechanical damage.3.2. Thermal Distribution Analysis (Thermal Uniformity)Simulation and experimental data clearly demonstrated that RF heating, due to its longer wavelength and better electric field penetration, performed significantly more uniformly than MW. The standard deviation of temperature at the center of the RF-treated pistachio bulk was 30 \text{ percent} lower than in a comparable MW treatment. This uniformity is crucial for secondary applications like roasting and pasteurization in high-capacity lines.

3.3. Comparison with MWWhile MW initiates the process faster, RF is preferable for materials requiring deeper penetration and minimal temperature gradients.4. ConclusionRadio Frequency technology is an advanced solution for addressing the closed-mouth pistachio challenge, thereby boosting economic efficiency. Furthermore, RF’s superiority in achieving thermal uniformity in large batches makes it an essential tool for precise pasteurization and roasting in the pistachio processing industry.