Post-harvest stages, including processing, drying, and storage, represent the final, critical opportunity for Pistachio Aflatoxin Reduction to meet export standards. This article provides a technical analysis of the engineering processes and advanced technologies employed at pistachio processing facilities. We will emphasize the precise management of moisture and the utilization of sophisticated Aflatoxin Sorting Technology based on UV Fluorescence, highlighting the capacity for the country to supply healthy products to sensitive global markets. Furthermore, we will explore novel non-chemical methods, such as Cold Plasma Decontamination, for residual contamination removal.Introduction: The Crucial Link to Quality Assurance

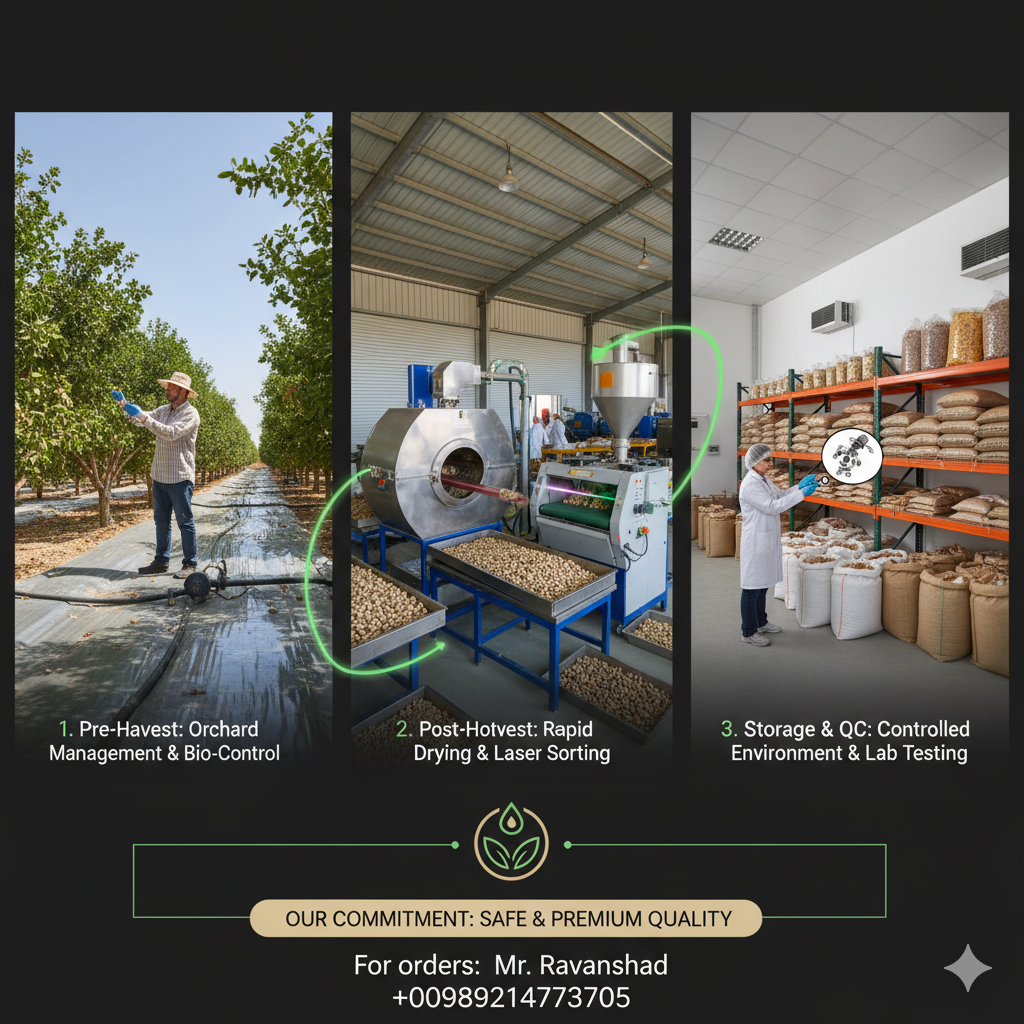

Even with the best orchard management, harvested pistachios may still contain residual fungal contamination. The primary goal of post-harvest processing is to immediately halt fungal growth and toxin production, followed by the precise segregation of contaminated nuts from the sound batch. Technology plays a pivotal role in these stages to ensure the final product truly deserves the reputation of Iranian Pistachio Quality.1. Critical Moisture Management: Halting Fungal GrowthThe A. flavus fungus requires moisture for growth and Aflatoxin production. Therefore, rapid and effective drying is the most crucial step in Pistachio Aflatoxin Reduction after harvest: * Hulling and Washing Process: Pistachios must be hulled and, if necessary, washed within a maximum of 24 hours after harvest. Delays in this process lead to a rapid increase in moisture and the onset of toxin production. * Moisture Standard: Studies confirm that Aflatoxin production increases exponentially at moisture levels above 9\%. The goal of the drying process is to rapidly reduce the kernel moisture content to below 6\% (preferably 4\% to 5\% for long-term storage and export). * Drying Methodology: Mechanical dryers with controlled airflow are superior to traditional methods (sun-drying) due to their speed, consistency, and precision in achieving the desired Pistachio Drying Standards.2. Advanced Aflatoxin Sorting Technology for SegregationPhysical segregation of contaminated pistachios is the single most effective way to lower the overall Aflatoxin level of a shipment. Optical technologies are central to this effort: * Color and Shape Sorting: These machines detect and separate pistachios with visual defects, stains, or abnormal shell coloration. These nuts are often associated with higher fungal contamination. * UV Fluorescence Sorting (Aflatoxin Sorting Technology): This is the most advanced method for detecting contamination. Aflatoxin exhibits a characteristic blue-green fluorescence when exposed to Ultraviolet (UV) light.

Mechanism: Smart sorters utilize highly sensitive cameras and sensors to pass the pistachios under UV light, identifying the contaminated nuts (which emit a blue-green glow) and ejecting them from the stream using high-speed air jets. * Efficacy: This process can significantly reduce the contamination level of the batch, bringing it below the stringent threshold required for export, especially in the EU market, thereby ensuring effective Post-Harvest Aflatoxin Control.3. Novel Decontamination Methods (Detoxification)In specific cases, particularly for batches slightly above the acceptable limit, novel non-chemical methods for toxin destruction are being explored: * Cold Plasma Decontamination: Recent research has demonstrated that Cold Plasma, by generating reactive oxygen species, possesses the capability to degrade the molecular structure of Aflatoxin. This chemical-free technique holds promise as a supplementary method in Pistachio Aflatoxin Reduction and detoxification efforts.4. Storage and Final Quality AssuranceAfter processing, pistachios must be stored under optimal conditions: * Storage Conditions: Warehouses must have excellent ventilation, low temperature (ideally below 10^\circ\text{C}), and controlled relative humidity. Any increase in moisture during storage can reactivate fungal growth and toxin production. * Final Testing and Certification: Prior to export, rigorous sampling and testing according to ISO and EU standards are mandatory to ensure the safety of the shipment and secure the necessary international health certificates.Conclusion

* A commitment to quality in the pistachio industry is a necessity, not an option. By integrating advanced drying techniques, UV Fluorescence Sorting, and novel decontamination methods, the control chain is completed, enabling the delivery of a premium, globally compliant product.

Post a comment Cancel reply

Related Posts

Logistics Engineering and Environmental Control in Global Pistachio Supply Chains

IntroductionThe transition of cargo through diverse climatic zones—from the arid regions of the Middle East…

Biochemical Stability and Mycotoxin Mitigation in Long-Haul Pistachio ExportAbstract

The preservation of pistachios (Pistacia vera L.) during extended maritime or overland transit is a…

The Green Revolution in Food Science: Pistachios as a Biomimetic Substitute for Animal Proteins and Savory FatsIntroduction

The transition toward sustainable protein sources has led food scientists to re-evaluate the pistachio as…

Advanced Phytochemical Applications of Pistacia vera in Functional Beverage Systems and Molecular MixologyAbstract

As of 2026, the global beverage industry has pivoted from simple hydration to “functional indulgence.”…