Optimization of Microwave Heating Conditions for Aflatoxin Risk Reduction and Accelerated Drying in Pistachio Processing (Case Study: Akbari Cultivar)AbstractThis research evaluates the impact of power and time variables in microwave (MW) treatment on two key pistachio processing parameters: controlling the growth of aflatoxin-producing fungi (Aspergillus flavus) and accelerating initial moisture reduction. Experiments were conducted on the Akbari pistachio cultivar using varying MW power levels (300 \text{W} to 900 \text{W}) and short exposure times (30 \text{s} to 180 \text{s}). Results indicated that rapid volumetric heating by MW, particularly under optimal conditions (power of 750 \text{W} for 90 \text{s}), led to a significant reduction in fungal microbial load and a higher rate of surface moisture removal. This technique demonstrates high potential as a rapid disinfestation pre-treatment in processing lines, aiming to enhance food safety and export quality of pistachios.

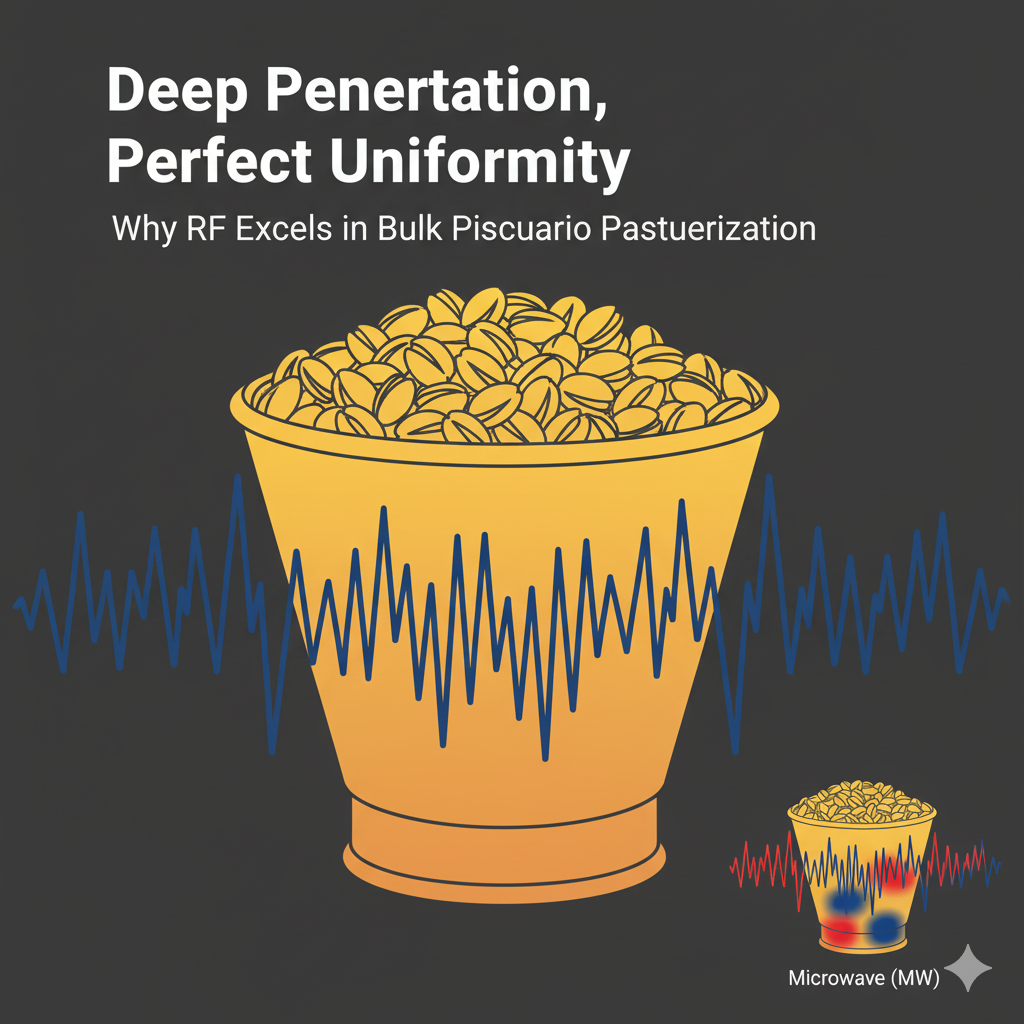

1. IntroductionPistachios, as a major Iranian export, are constantly exposed to contamination by mycotoxins, particularly Aflatoxin. Traditional, prolonged hot-air drying methods and inadequate storage conditions exacerbate this risk. Microwave dielectric heating, due to its ability to generate volumetric heat within water molecules and its high speed, has emerged as a promising non-conventional alternative.2. Materials and MethodsAkbari pistachio samples with an initial moisture content of 8 \pm 1 \text{ percent} (wet basis) were prepared. Treatments were performed in an industrial-grade microwave oven with adjustable power and time settings. * Fungal Analysis: Specialized culture media were used to enumerate Aspergillus flavus colonies before and after MW treatment to assess contamination levels.

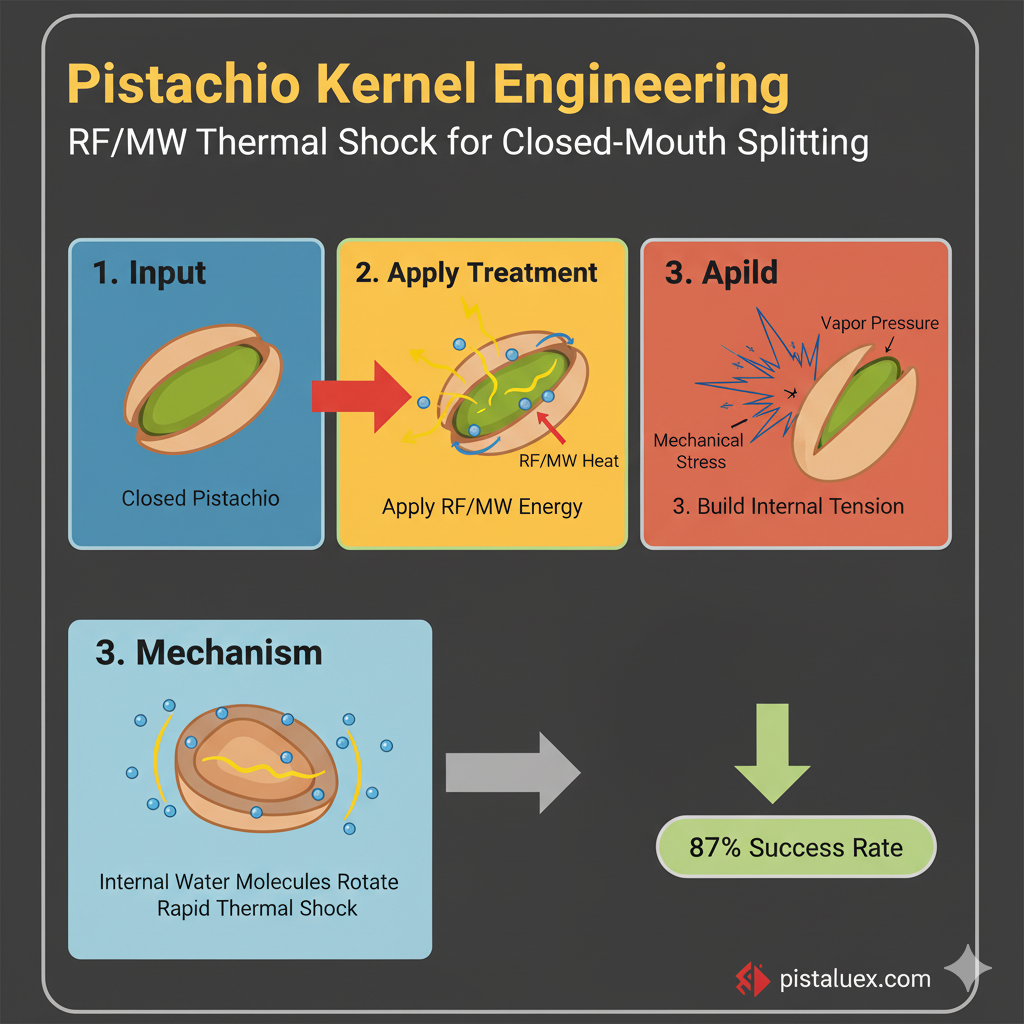

* Moisture Measurement: Product moisture content was measured before and after treatment using a vacuum oven (reference method). * Quality Assessment: Color parameters (L*, a*, b*) and texture (fracture hardness) were recorded to evaluate potential side effects of the thermal treatment.3. Results and Discussion3.1. Impact on Fungal Control (Thermal Disinfestation)Increasing MW power and treatment time correlated directly with a logarithmic reduction in microbial load. At high power levels, the thermal shock resulting from rapid internal moisture vaporization led to the destruction of fungal cell walls and their inactivation. These findings emphasize the potential of MW as a Pathogen Reduction Process (PRP).3.2. Drying PerformanceMW treatment significantly accelerated the drying rate. Compared to hot-air methods, the time required to reduce the pistachio moisture content by 1 \text{ percent} was cut to approximately 1/5 of the conventional time. This reduction in overall processing time helps prevent the activation of lipolytic enzymes, which cause rancidity.3.3. Sensory Quality PreservationTreatments with short duration and high power had the least detrimental effect on color (high L)* and texture hardness. Longer treatments resulted in increased browning (reduced L*) and diminished kernel crispness.

4. ConclusionThe optimal use of Microwave Heating as a short pre-treatment can minimize the risk of Aflatoxin contamination and accelerate the drying process. This method, while substantially preserving product quality, represents an effective step toward elevating the export standard of Iranian pistachios.

Post a comment Cancel reply

Related Posts

Logistics Engineering and Environmental Control in Global Pistachio Supply Chains

IntroductionThe transition of cargo through diverse climatic zones—from the arid regions of the Middle East…

Biochemical Stability and Mycotoxin Mitigation in Long-Haul Pistachio ExportAbstract

The preservation of pistachios (Pistacia vera L.) during extended maritime or overland transit is a…

The Green Revolution in Food Science: Pistachios as a Biomimetic Substitute for Animal Proteins and Savory FatsIntroduction

The transition toward sustainable protein sources has led food scientists to re-evaluate the pistachio as…

Advanced Phytochemical Applications of Pistacia vera in Functional Beverage Systems and Molecular MixologyAbstract

As of 2026, the global beverage industry has pivoted from simple hydration to “functional indulgence.”…