Aflatoxin, one of the most critical mycotoxins produced by species of the Aspergillus fungus (particularly Aspergillus flavus and A. parasiticus), represents the greatest health and commercial challenge to the Iranian pistachio export industry. This scientific article focuses on the paramount importance of preventive measures during the pre-harvest stages. Research findings indicate that intelligent management of environmental stresses, orchard structural optimization, and the implementation of innovative methods such as biological control (Biocontrol) are key to Pistachio Aflatoxin Prevention and ensuring product compliance with stringent international standards.Introduction: Global Significance and the Nature of ContaminationAflatoxin contamination, especially Aflatoxin B1, a potent liver carcinogen, directly impacts the rejection of export shipments and the reputation of Iranian pistachios in global markets. The production of this toxin often begins in the field under conditions of stress and high humidity, particularly when the kernel is exposed to fungal invasion (e.g., through Early Split Pistachios or mechanical damage). Adherence to scientific strategies is the only pathway to achieve the export quality required by markets like the European Union (EU), which typically set maximum limits for Total Aflatoxin around 4 parts per billion (ppb).1. The Mechanism of Contamination and Influencing Environmental FactorsThe A. flavus fungus survives as a saprophyte in the soil. Contamination occurs when the pistachio kernel is exposed to fungal attack. Critical conditions that significantly elevate the risk of contamination include:

* Hull Damage: Cracks, mechanical injuries, and damage caused by pests like the Stink Bug and the Navel Orangeworm serve as primary entry points for the fungus to reach the kernel. * Early Splitting: The hull of these pistachios opens prematurely, leaving the kernel vulnerable to environmental contamination and insect vectors. * Moisture and Temperature Stress: Prolonged periods of drought stress during the critical kernel-filling stage and high temperatures (between 30^\circ\text{C} to 37^\circ\text{C}) create the ideal conditions for A. flavus growth and toxin production.2. Comprehensive Agronomic and Orchard Management StrategiesEffective Aspergillus flavus Management must start from the establishment and maintenance of the orchard: * Orchard Structural Optimization: Adhering to standard planting distances and uniform variety selection to synchronize harvest times is crucial. This aims to improve air circulation, reduce relative humidity, and facilitate timely agricultural operations.

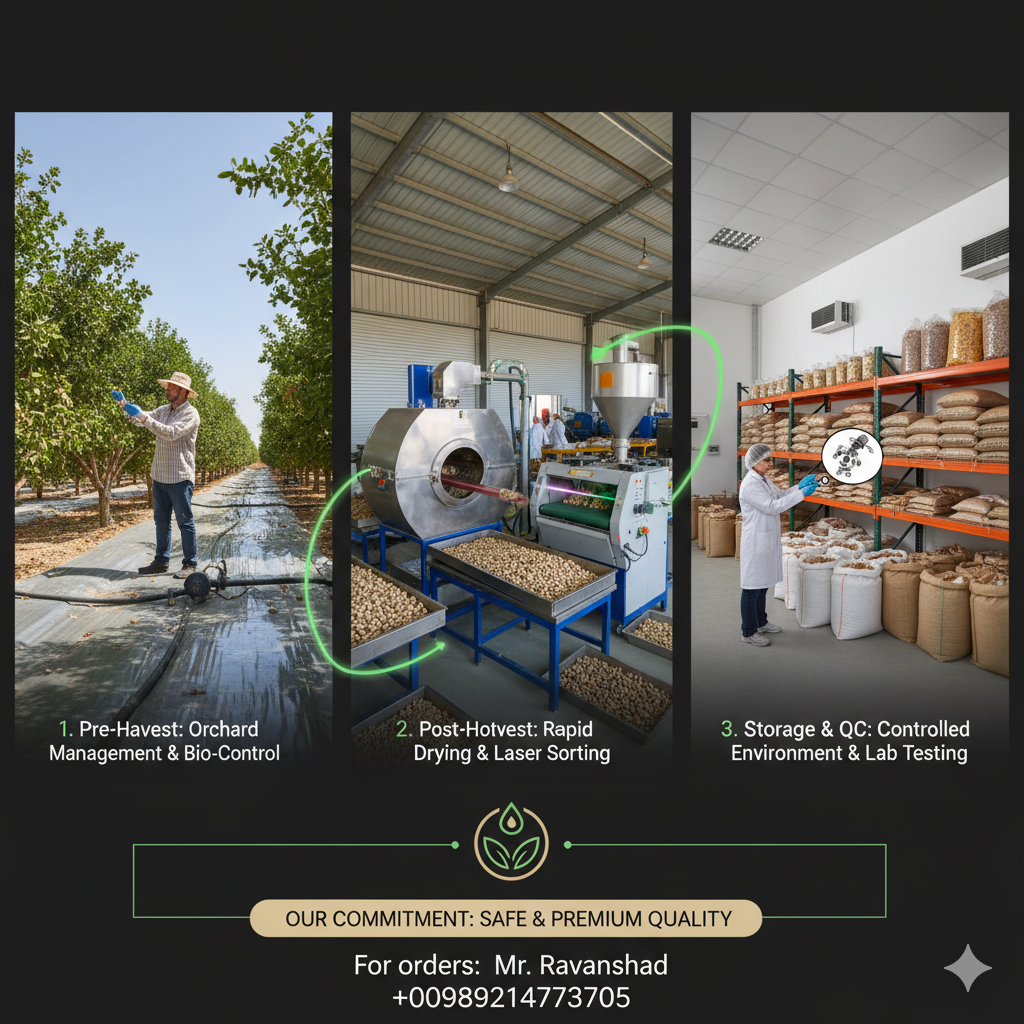

* Water and Nutrient Management: Implementing precise Pistachio Irrigation Management regimes and avoiding water stress, especially during kernel development, is essential. Adequate provision of critical elements like Calcium (to increase hull resistance) and Potassium is also vital for boosting the tree’s natural defenses and reducing environmental stress. * Key Pest Control: Utilizing Integrated Pest Management (IPM) techniques to control insects such as the Stink Bug, which is a primary aggressor of the pistachio hull. This is necessary to seal off the fungus’s entry points to the kernel, thereby significantly contributing to pre-harvest Pistachio Aflatoxin Prevention.3. Biological Control of Aflatoxin: The Key InnovationThe most effective preventative measure in recent years has been the application of Biological Control of Aflatoxin techniques. This approach involves: * Application of Non-Toxigenic Strains: Utilizing indigenous strains of the A. flavus fungus that lack the ability to produce the toxin (non-toxigenic strains). These harmless strains are introduced into the orchard soil, where they compete with the toxigenic strains for food sources and effectively colonize the area. * Research Outcomes: Based on successful research conducted in Iran, the successful application of these biocontrol agents has been proven to substantially reduce field contamination levels, marking a fundamental step in sustainable Pistachio Aflatoxin Prevention.4. Harvest and Post-Harvest Transition ProtocolsThe timing and method of harvest are two decisive factors: * Timely Harvest: Delaying the harvest dramatically increases the risk of contamination, particularly for varieties that exhibit early splitting. Harvesting must be done at peak maturity and as quickly as possible. * Initial Segregation: During harvesting and transportation, it is imperative to promptly segregate suspicious, stained, or Early Split Pistachios from the main bulk to prevent them from becoming sources of contamination for healthy nuts.ConclusionSuccessful Aflatoxin control in pistachios is a complex, knowledge-based process whose efficacy relies on the strict implementation of comprehensive orchard management strategies. By investing in Biological Control of Aflatoxin, rigorous pest management, and optimal soil and water resource utilization, the threat of Aflatoxin B1 can be mitigated, transforming it into an opportunity to guarantee superior quality and ensure the success of Pistachio Aflatoxin Prevention.